Top Links

Journal of Nutrition and Health Sciences

ISSN: 2393-9060

Enzyme Assisted Extraction of Polyphenols from the Old Tea Leaves

Copyright: © 2016 Hai TC. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Related article at Pubmed, Google Scholar

Polyphenols are a main antioxidant in the old tea leaves. These bioactive compounds have been linked with a reduced of risk cardiovascular and cancer. In this study, the enzyme cellulase was used to extract phenolic compounds (polyphenols) from the old tea leaves. The parameters such as ratio of enzyme and raw materials, pH and time of extraction were investigated to affect on polyphenol extraction process and kinetic equation. According to our research results, the ratio of enzyme raw material was 2% at the pH 5.5, and these samples were incubated at 50 °C in 60 minutes that gave the best extraction results. The total of phenolic content and the purity reached 85.05 mg GAE/g dry matter and 25.65% respectively. The extraction kinetics of phenolic and the ability of cellulase enzyme extraction (Ce) rose a 1.1 times compared with the control sample, the extraction rate constant k changed a little and the initial extraction rate vo found no significant difference.

Keywords: Polyphenol; Enzyme cellulase; Kinetic extraction

Tea is the most widely consumed beverage in the world and it is known for the various health benefits. In recent year, tea is not only used as fresh drink but also traditional flavor in food product [1]. Polyphenols in green tea are believed as excellent free radical scavengers. Green tea polyphenols are believed to be responsible for cancer preventive effect, and the antioxidant activity of green tea polyphenols has been in complicated as a potential mechanism [2]. The green tea phenolic compounds of highest concentration are gallic acid (GA), (–)-gallocatechin (GC), (+)-catechin (C), (–)-epicatechin (EC), (–)-epigallocatechin (EGC), (–)-epicatechin gallate (ECG), (–)-epigallocatechin gallate (EGCG), p-coumaroylquinic acid (CA), and (–)-gallocatechin-3-gallate (GCG) [1-5].

In the tea industry, the fresh tea shoot (Camellia sinensis) including 2 – 3 leaves unfurled was used to make green tea products but the old tea leaves were removed as sub products [4,5]. The old tea leaves contain a lot of tannin that are the cause of bitterness in the extracts. Today, there are many previous studies on extraction of polyphenols that have been done with different methods. The most commonly solvents using for extraction are hot water and organic solvents [3]. However, enzyme assisted extraction has been successfully used for extraction from biological active compounds, especially polyphenols in ambarella fruit, Fumaria officinalis and strawberry,… but on the old tea leaves, it is still limited [6-8]. Assisted enzyme extraction helps to increase the recovery efficiency polyphenol compounds [3,4]. The most distinctive feature of enzymes is that they can effectively operate at mild physiological conditions, at atmospheric pressure and pH of 3-10 [6,9,10]. Therefore, in this study, we conducted a survey to assess the effect of cellulase to polyphenol compounds that were extracted in the old tea leaves and enhance the use of the old tea leaves in the production from this material.

Materials

Old tea leaves were harvested from Loc Chau, Bao Loc, Lam Dong province, Viet Nam. Tea leaves were inactivated enzyme by steaming from 95 °C to 100 °C for 5 minutes and dried from 40 °C to 50 °C for 8 hours. Then they were crushed and stored in sealed plastic bags to avoid direct sunlight.

Chemicals

Folin - Ciocalteu agent and Gallic acid were purchased from Merck, methanol (Aldrich – Sigma) Na2CO3, ethanol (China).

Cellulase (Cellulase 1.5L) was derived from Trichoderma reesei and manufactured by Novo Nordisk Ferment (Switzerland). It has an activity of 700 EGU/g with a density of 1.22 g/ml.

Preparation the polyphenol extracts: Dried old tea leaves were crushed to 0.5 – 1.0mm, and 50g of old tea leaves were used in each assay. The samples were placed into 1000 mL flasks. The obtained dried tea leaves were mixed with water at the weight ratio of 1:15 preparing for extraction.

Effect of enzyme concentration on the extraction of polyphenols: Enzyme cellulase was added into the flask with different concentrations. The enzyme concentrations were changed between 0, 0.5, 1, 1.5, 2 and 2.5%v/w, and incubated at 40 °C in 20 minutes at pH 4.5. After that, cellulase in these mass extracts was inactivated at 90 °C in 5 minutes. The control sample (without enzyme assisted extraction) was conducted extraction at 90 °C. Then the mass extractions were carried out to centrifugation at 3500 rpm in 10 minutes.

Effect of pH on the extraction of polyphenols: The pH was surveyed at different values, its values including 3.5, 4.5, 5.5, 6.5, 7.5 and these samples were incubated at 40 °C in 20 minutes. The enzyme concentration was optimized from the experiment above. Then enzyme in these mass extract was inactivated at 90 °C in 5 minutes.

Effect of enzymatic treatment time on the extraction of polyphenols: Time treatment was changed in 0, 20, 40, 60, 80 and 100 minutes. The enzyme concentration and pH were optimized from the experiments above. Then enzyme in these mass extract was inactivated at 90 °C in 5 minutes.

Folin-ciocalteu method, is one of several methods which are used to determine total polyphenols. Polyphenols reduce Folin agent (yellow solution of polyphosphatetungstenate and molydate) in mild base medium to form deep blue color [3,11]. The total polyphenol level (TP): was evaluated by spectrophotometric method using Folin-Ciocalteu reagent at 765 nm [3,11]. The results were expressed as the equivalent to mg of gallic acid per litre of extract (mg GAE/L).

The total polyphenol purity: The crude TP was dynamically adsorbed on a glass column packed with AB-8 resin. Based on the result of the static AB-8 resin adsorption experiments, the equilibrium time was chosen as 4 h. Distilled water was first used to remove sugars, acids and other water-soluble compounds. Then, the crude PP was eluted with ethanol at a constant flow velocity of 1.5 mL/min, and two bed volumes (BV) of phenolic eluent was collected and concentrated in a rotary evaporator to afford the purified PP. The total polyphenol purity (PP) in the mash extraction wass calculated by the ratio of the weight of purified polyphenols in mash extraction and the total solids weight (g).

Whereas:

- mPP: the weight of purified polyphenol in the mass extraction (g).

- mCKD: the total solids weight (g).

Catechins were measured using HPLC method described in previous literature with modified [5,9]. Analyses were performed on an HPLC 1100 Agilant, with C18 column (Synergi Hydro-RP 80R, Phenomenex, US) and UV detector (230 nm). Eluent A was acetonitril (ACN) and eluent B was 0.1% aqueous phosphoric acid, the flow rate was kept constant throughout the analysis at 1 ml. min-1.

To determine the extraction rate constant of the antioxidants, the second-order rate law was applied [2]. The general second-order model can be written as:

Where: k is the second-order extraction rate constant (L/g.min), Ce is the extraction capacity (the equilibrium concentration of antioxidants in the extract) (g/L), and Ct is the concentration of the extract at a given extraction time (g/L).

The integrated rate law for a second-order extraction, under the boundary conditions t = 0 to t and Ct = 0 to Ct, can be written as an equation (3) or a linearized equation (4):

The initial extraction rate, vo (g/L.min), as Ct/t when t approaches 0, can be defined as equation:

All experiments were performed in triplicate. Means were compared by multiple range tests with p < 0.05. Analysis of variance was done to use the software Statgraphics plus centurion XVI. Optimization parameters were used by software Modde 5.0.

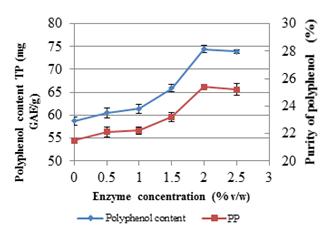

Enzyme was employed in the experiment because it is non-toxic and a green solvent. The result on Figure 1 showed that the sample was untreated with enzyme, the total polyphenol level achieved at 58.75 mg GAE/g dry matter. It was lower than that of these samples which were treated with enzyme. When enzyme concentration increased from 0.5% to 2.5%, the total polyphenol content and the purity of polyphenol in mass extracts increased dramatically. The maximum total polyphenol content (TP) achieved at 74.45 mg GAE/g and 25.39% of polyphenol purity at 2%v/w of enzyme concentration. It was higher 22.99%, 21.3% and 12.99% than that of the samples treated with enzyme at 0.5%, 1% and 1.5%v/w. However, when the cellulase concentration increased to 2.5%v/w, the total polyphenol level and the purity of polyphenol decreased slightly and insignificantly to compare with the sample that was treated at 2%v/w. The reason for this may be that as more amount of enzyme is added, the more cell wall polysaccharides are hydrolyzed, especially the linkage between polysaccharide-lignin network that released more amount of polyphenol compounds [6,10,12]. Another mechanism may be the direct enzyme catalyzed breakage of the ether and ester linkages between phenol and plant cell wall polymers [7,8,13,14]. According to Yang-Hee Hong, et al. the total polyphenol level increased 4.25% when using cellulase to assist extraction (from 2.35 mg/ml to 2.45 mg/ml) [14].

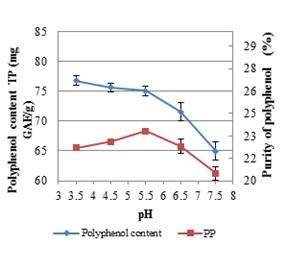

Polyphenols concentration in the extracts was rapidly decreased when increased pH value from 3.5 to 7.5 (Figure 2). At pH 3.5, the maximum total polyphenol level in mass extract was 76.76 mg GAE/g and the lowest polyphenol concentration at pH 7.5 (64.95 mg GAE/g). There was insignificantly the total polyphenol level in the mass extract when pH of the extraction achieved at 3.5, 4.5 and 5.5 each (P > 0.05). Its value decreased to 9.19% when increasing pH from 6.5 to 7.5 (71.52 mg GAE/g to 64.95 mg GAE/g).

The purity of polyphenols in the mass extract did not similar trend with the recovery of polyphenol content in the mass extract. The highest purity of polyphenol level got a peak at pH 5.5 (23.31%) then it reduced when increasing pH value from 6.5 to 7.5 (22.29% and 20.49% respectively).

The reason of this trend could be explained by the pH optimum of cellulase at pH 4.5 [9-11]. According to Karan Vasisht, et al. pH affects to stability of cellulase on extraction polyphenol from the bud tea and polyphenol compounds in the mass extraction, at pH 1.2, 2.0 and 4.0, its value reduced to 2.6%, 2.7% and 2.7% each to compare with pH 5.0 [9,10].

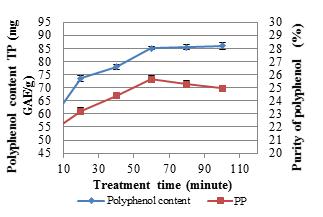

Polyphenol concentration in the extracts increased rapidly when increasing time treatment (Figure 3). The treatment time was 60 minutes, the total polyphenol content reached at 85.05 mg GAE/g, its value increased 1.58 times and 1.56 times to compare with these samples that were treated at 10 minutes, 20 minutes respectively. The purity of polyphenol in the mass extract also increased and reached the maximum value at 60 minute extraction, it’s about 25.65%. This value reduced slightly when the extraction time over 60 minutes. Longer enzyme treatment time generated high level of hydroxyl radical in the presence of oxygen that lead to a negative impact on the purity of polyphenol. Furthermore, longer enzyme treatment time effects to polyphenol purity through releasing amount of reduced sugar and insoluble protein in the mass extract [2,3].

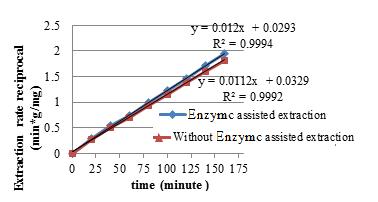

The result in figure 4 showed that the kinetic parameters including extraction capability (Ce), extraction rate constant (k) and the initial extraction rate (vo) changed and differed between these samples with assisted extraction by cellulose and non-enzyme assisted extraction. The extraction capability of sample with cellulase assisted extraction achieved at 89,300 mg/g and it’s higher nearly 1.1 times than that of these samples without assisted enzyme (82,874 mg/g). It proved that cellulase supported for phenolic extraction, two parameters: the extraction rate (k) and the initial extraction rate changed but insignificant (Table 1) (Figure 4).

Similar kinetic parameters were recently reported by Tuyen T, et al. and Le, et al. for polyphenol extraction from Ambarella fruit and grape fruit. However, the values and the increase in the kinetic parameters estimated by these authors were much lower than those in our study.

We analyzed catechin compounds in the mass extracts by reversed phase HPLC. And the results showed that the catechin compounds in the old tea leaves were extracted by enzyme accounted for 14.52% dried weight (Table 2). It was higher than that of the control sample (without enzyme assisted extraction). C, EC, EGCG and ECG in the mass extracts with enzyme treatment were 45.7 %, 2.73%, 10.87% and 40.05% higher than these catechin compounds without enzyme assisted extraction.

Therefore, enzyme should be used as a main method for extraction.

Cellulase enzyme had the positive influence to extraction polyphenols in the old tea leaves mass. Phenolic concentration increase 7.73% to compare with raw materials not using cellullase enzyme supporting extraction. Optimal conditions of processing when using cellulase to assist extraction including: the ratio of cellulase and raw materials was 2% (v/w), pH 5.5, and extraction processing was conducted at 50 °C in 60 minutes. Meanwhile, phenolic concentration obtained 85.05 mg GAE/g and its purity was 25.65%.

The dynamic of cellulase assisted extraction showed that the extraction ability (Ce) increased 1.1 times higher than sample with non-enzyme assisted extraction, extraction rate constant (k) changed but not significantly, and the initial extraction rate (vo) had no difference (P > 0.05).

|

Figure 1: Effects of cellulase concentration on the polyphenol level and the purity of polyphenol on the tea leaves mash extract |

|

Figure 2: Effects of pH concentration on the polyphenol level and the purity of polyphenol on the tea leaves mash extract |

|

Figure 3: Effect of extraction time to phenolic content and phenolic purity |

|

Figure 4: Extraction rate reciprocal (t/Ct) of polyphenol at different extraction times (t) in enzyme-assisted extraction |

Sample |

Extraction capability Ce (mg/g) |

The initial extraction rate vo (mg/g.min) |

Rate of extraction k (g/mg.min) |

|---|---|---|---|

Enzyme assisted treatment |

82.874 ± 0.398a |

0.005 ± 0.0002a |

34.352 ± 1.180a |

Without enzyme assisted treatment |

89.300 ± 1.393b |

0.003 ± 0.0004b |

30.520 ± 2.096a |

* Values with different letters in the same column are not significantly different at the level of p = 0.05 |

|||

Catechin (% dried weight) |

|||||

|---|---|---|---|---|---|

C |

EC |

EGCG |

ECG |

Total |

|

Enzyme assisted treatment |

0.94 |

1.83 |

9.01 |

2.74 |

14.52 |

Without enzyme assisted treatment |

0.51 |

1.78 |

8.03 |

1.63 |

11.85 |

| Table 2: Analytical catechin compounds of tea extracts | |||||