Top Links

Journal of Materials Science and Nanotechnology

ISSN: 2348-9812

A Review: Fiber Reinforced Polymer Composite Helical Springs

Copyright: © 2017 Yahya Kara. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Related article at Pubmed, Google Scholar

In order to successfully reduce the weight of a helical spring it is possible to optimize the material parameters or to use alternative advanced materials instead of conventional engineering ones. Springs are used for vibration damping in mechanical systems and are generally made of steel. As an alternative to material of steel springs in the scope of the study, mechanical behaviors of fiber reinforced polymer (FRP) composite helical springs have been investigated. The FRP composite material has made it possible to reduce the weight of helical spring without any reduction on load carrying capacity. Due to increasing competition and innovation in recent decades, vehicle industries show interest in replacing conventional steel spring with FRP composite helical spring which has advantages such as higher strength to weight ratio, higher stiffness, high impact energy absorption and lesser stresses. The study gives the brief look on the suitability of FRP composite helical springs on related mechanical systems. The objective of the present work is evaluation of the design, analysis and fabrication of FRP composite helical springs.

Keywords: Composite helical spring; Fiber reinforced polymer (FRP); Composite material, Helical spring

Helical springs are essential machine elements on numerous engineering applications. They are necessary to minimize the characteristics such as weight, vibrations, impacts, and bumps due to variable conditions and create suitable operational structures. This springs are commonly used in mechanical suspension systems as damping element and often use in industries such as automotive, airplane and train. The fuel efficiency and gas emission regulations of automobiles are two important issues nowadays [1,2]. Weight reducing in automobiles is an excellent solution since it saves energy and improves vehicle performance [3]. For the application of lightweight materials instead of conventional ones, it is important to consider environmental and mechanical properties such as specific strength, deformation, stiffness and impact resistance [4]. Furthermore, it is very important to reduce the weight of vehicle components to improve efficiency for especially electric and hybrid vehicles [1,5]. Metal and their alloys, which are conventional engineering materials, are used as spring material but conservation of metals is an important issue in these days. Increasing innovations and competition in engineering tends to modify and develop the existing products or replacing old products by new and advanced material properties. More interesting aspect is, by combining two or more materials can obtain improved mechanical properties of materials, such as composites. Especially, the FRP composites have more elastic strain energy storage capacity, high strength to weight ratio and stiffness [6].

Fiber reinforced polymer composite (FRPC) technology into the industry is less than a century old. The polymers taking bold steps had been emerged just at the beginnings of 1900 by chemists and industrialists. The first known FRPC was used in manufacturing of boat hull in the mid 1930’s with reinforce the polyester resin with fiberglass [7]. In the recent time, researchers have created a material with high properties which can defy to high speed impact, like aramid fiber reinforced composite stopping bullets. The Airbus A380, the world’s largest passenger aircraft, makes use of modern composites in its design. More than 20% of the A380 part is made of composite materials, mainly carbon fiber reinforced composites. This design is the first large scale usage of glass fiber reinforced aluminum which is 25% stronger than conventional airframe aluminum but 20 % lighter [1,8]. FRPCs are used in almost every type of advanced engineering structure, with their usage ranging from aircraft, helicopters and spacecraft through to boats, ships and offshore platforms and automobiles, sports goods, chemical processing equipment and civil infrastructure such as bridges and buildings.

For these reasons, one of the important machine element as helical springs made of steel can be replaced by composite ones. Thereby, utilization of fiber reinforced polymer (FRP) composite materials in the automotive, train and aerospace industries is being increased due to their high specific stiffness and strength [9].

Among the different types of mechanical springs, helical springs are commonly integrated as parts of many mechanical systems. Application of polymer composite structures reduces the weight of springs without any reduction on the load carrying capacity in corresponding mechanical system [10].The first major application of fiber reinforced composites is the rear leaf spring; introduced first in 1981, in which Daugherty developed composite leaf springs for heavy trucks [11]. Nowadays, FRP composite helical spring is attracted the interest of many researchers but there is limited research on it.

The main objective of this paper is to review the compile and evaluate the information from the open literature on feasibility of FRP composite helical springs. Different methods which have been employed in the existed researches are investigated and then corresponding pros and cons are analyzed.

The application of FRP composite in the manufacture of helical springs is not much popular. A limited number of research papers have been published on the mechanical analysis and manufacturing of FRP composite helical springs Figure 1. A brief review of some selected references on this topic is presented:

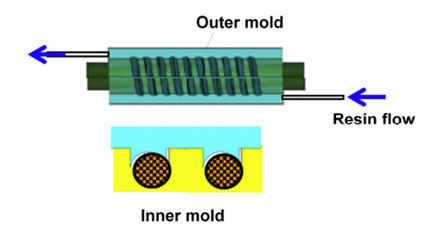

Choi B.L and Choi B.H investigated on carbon fiber reinforced epoxy composite coil springs considering the static spring rate. In their research study, CFRP coil spring manufactured using the resin transfer molding (RTM) process, as shown in Figure 1. During the RTM process, carbon fiber freeform is filled with epoxy resin and hardened by crosslinking under vacuum conditions. Produced springs have tested to determine static spring rate by enforced displacements tests. Also, their paper proposed effective deterministic processes for developing composite coil springs through the application of computational and experimental methods. In their study, all of the design parameters for composite spring with the same spring rate as a steel one have been investigated. The produced CFRP helical spring fiber volume ratio and void volume ratio are determined as 64.4% and 3.5%, respectively, by the researchers. In their study, the equivalent shear modulus of the composite predicted from the inverse relationship between the twist angle and the shear modulus. The magnitude of the shear modulus for a composite with a 45° ply angle found to be approximately 16.8% of that of steel. According to obtained data’s of their research study, the estimated shear modulus was in good agreement with their experimental results. Their research shows that coil spring made of CFRP is provide weight reduction about 55% than that of steel [12].

Bakhshesh M. and Bakhshesh M. worked on three different composite helical springs which are made of E-glass/Epoxy, Carbon/Epoxy and Kevlar/Epoxy. RTM process is used for manufacturing spring. The optimum designs based on the parameters of weight, maximum stress and deflection and have been compared with steel helical springs. It has been shown that spring optimization by material spring changing causes reduction of spring weight and maximum stress considerably. The loading conditions are assumed to be static in their study. Spring shear stress and displacement have been obtained both finite element method (FEM) and analytically, and has been compared with steel helical spring. It is seen that both numerical and analytical results were in good agreement. Shear stresses under effect of fiber angle are investigated for three type composite spring in this research. It is obtained that spring has the most shear stress when fiber position has been considered to be in direction of loading. Their research shows that the composite helical springs have lesser stress and has the most value when fiber position has been considered to be in direction of loading. The most safety factor is related to case that fiber position has been considered to be perpendicular to loading and it is for carbon fiber reinforced polymer (CFRP) composite helical spring. Also, results show that CFRP spring weight is less than all other. Obtained results of both composites and steel spring are shown in Table 1 [13].

T. S. Manjunatha and D. Abdul Budan have experimented on the strength of the helical spring with the use of FRP composites. Three different materials like glass fiber, carbon fiber, glass/carbon fiber in +45 degree orientation are used for helical spring and tested their mechanical behavior. Filament winding technique (FWT) has used to manufacture composite helical springs. In their study, a mandrel (cast iron or any other metal), which having the shape of the spring profile is prepared for winding process. This mandrel is fixed between the centers of the lathe. A mould release agent silicone gel has been applied on the mandrel. The fibers have been cut in +45 degree orientation because the acting load on the compression spring is shear. After that, the fiber tape dipping in the epoxy resin has been wound on the mandrel. In their research, they have continued to winding till the desired thickness of helical spring achieved on the mandrel. The curing process has been applied as 24 hours in the atmospheric temperature by researchers. After that, they realized related physical tests to determine some mechanical properties such as spring stiffness, failure load, maximum compression and shear stress to manufactured composite springs. According to these, spring rate of the carbon fiber spring is found to be 24% more than the glass fiber spring and 10% more than the glass/carbon fiber spring. The related mechanical properties of composite springs are given in Table 2.

Obtained results show that the weight of the spring manufactured from fibers is less than steel spring. However the cost of the composite springs is higher than the steel springs. As a result of their research study, composite helical springs are providing good stiffness and low weight system than conventional material systems [14].

C.H. Chiu et al. investigated four different types of composite helical springs which are made of unidirectional laminates (AU), rubber core unidirectional laminates (UR), unidirectional laminates with a braided outer layer (BU), and rubber core unidirectional laminates with a braided outer layer (BUR). The general structural illustrations of these are given in Table 3.

Main objective of their study is aim to determine the effects of rubber core and braided outer layer on the mechanical properties of those of composite helical springs. It is obtained that the helical composite spring with a BUR structure has the highest mechanical properties among the four types of helical composite springs, its failure load in compression approximately equals 3297 N and the spring constant is almost 160 N/mm. According to the result have been obtained, the helical composite spring with a rubber core can increase its failure load in compression by about 12%; while the spring with a braided outer layer can not only increase its failure load in compression by about 18%, but also improve the spring constant by approximately 16% [15].

Sequeira, A. A et al. in their research paper discussed the behavior of carbon and kevlar composite helical spring and steel helical spring with related to light vehicle suspension system investigated by a static analysis. Aim of their study to compare the mechanical properties of composite helical spring with steel helical spring in area like load carrying capacity, stiffness and weight saving of FRP composite spring. Design parameters, such as outer and inner coil diameters, pitch length, height etc., of three helical springs were chosen the same. They investigated some mechanical behavior of all springs by numerically in ANSYS software. Mesh size, number of nodes and number of elements have been determined equal for all helical spring in the ANSYS. Their researches show that the specific modulus (young’s modulus (E) upon mass density of the material (ρ)) of CFRP composite spring is the highest and kevlar FRP (KFRP) is lowest. Load & deflection characteristics of steel spring have been found better than composite ones. However, mass of the KFRP helical spring has been determined less than CFRP and steel ones. The weight of the CFRP spring is very low compared to the steel spring and it is very beneficial to use carbon spring instead of steel spring to reduce the overall weight of the related mechanical systems [16].

Ekanthappa, J. et al. studied on the fabrication and strength of glass fiber reinforced epoxy composite helical springs. They manufactured GFRP composite spring by FWT because of simple setup and low cost. In this, a mandrel, which is re-usable, easy to fabricate and very convenient for the fabrication, is prepared by mild steel material. In their study, curing process has determined as two hour for composite spring. It has been observed that weight of GFRP composite helical spring is 40% less than steel spring. In their paper, they proposed that the cost of GFRP composite spring is greater but it can be compensated by amount of fuel saved by using this GFRP spring. Their research shows that the stresses developed within GFRP coil springs are less. Therefore, researchers expect that composite springs exhibit high fatigue life in comparison with steel springs. However, they observed that GFRP composite spring has lower stiffness than the equivalent steel one [17].

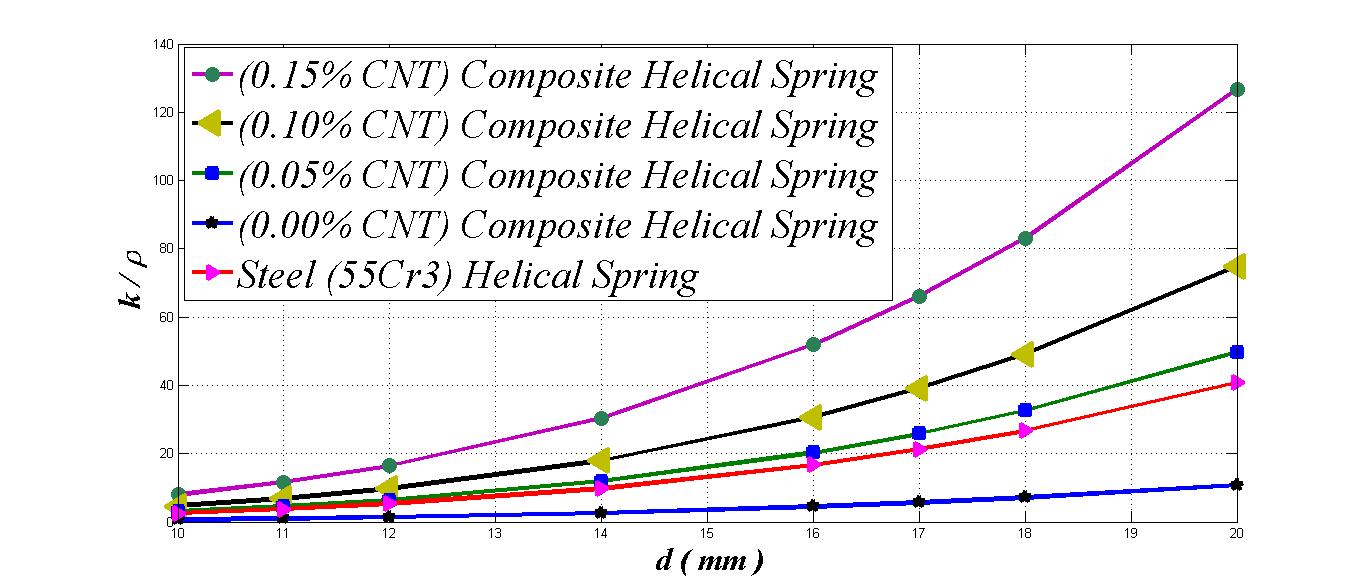

Kara Y. and Akbulut H. studied mechanical behavior of carbon fiber reinforced and carbon nanotube (CNT) additive epoxy composite helical springs. In their study, addition of CNT at various rates into epoxy resin has investigated in the CFRP helical springs deformations and shear stresses behaviors by analytically and numerically. Their study describe that how mechanical properties, such as Young’ modulus, shear modulus, Poisson’s ratio etc., of CNT additive CFRP composite helical spring determine by micromechanics approach. In the study, obtained results are compared with conventional steel helical springs and feasibility of nanocomposite springs is discussed. According to their research study, comparing steel and CNT additive FRP composite helical springs with same dimensions, the stiffness values of FRP composites springs are less than that of steel ones. However, considering of material densities, carbon fiber reinforced CNT additive composite springs have better specific spring stiffness values, as shown in Figure 2. In their research study, a geometrical optimization has proposed for nanocomposite helical springs due to weak behaviors against to steel springs. When the wire diameter of 0.15% CNT additive composite helical spring increases 15%, it has equal spring stiffness with steel one. When CNT volume fraction increases, deformation value becomes low and spring stiffness value becomes increase. This is highly desirable phenomenon in designing of helical springs [1].

Sancaktar E. & Gowrishankar S. have carried out the works on the effects of number of active coils, ratio of diameters of maximum cylinder to the diameter of the wire and material types on the fundamental natural frequencies of composite helical springs with circular cross sections. In the study, glass, carbon and hybrid fiber reinforced epoxy composite helical springs have manufactured by FWT. Their paper discusses the experimental natural frequency analysis of composite helical springs. In their study, the experiments performed for three type composite springs, which have coil numbers as 6 and 7, and for different coil/wire diameters to determine the influence of these variables on the natural frequencies. In this aim, helical springs of three different coil and wire diameters are investigated by researchers. Therefore, three different PVC pipes, which are provide desired inside diameters for fiber strands have been selected to form the spring wire diameter. The procedures for the fabrication of helical springs are broken down into three stages by researchers. First stage realize as the determination for amount of glass/carbon fiber strands accommodation into PVC tube. Second stage is consisted of resin bath to fiber strands. In the third stage, a PVC pipe of a specific diameter was mounted on to the winder to manufacture the spring. In this stage, coil diameter has been determined and final shape has been given to the composite helical springs. Detailed information of composite helical spring fabrication steps can be found in the related literature [18]. It can be said that this novel fabrication method, which is offered by researchers seems low cost and more versatile. Obtained results show that natural frequency of composite helical springs can be lowered by increasing the coil diameter, in turn increasing the D/d ratio, and also by increasing the number of turns [18].

Shende, M. A. et al. have investigated failure analysis of GFRP helical coil spring by both numerically and experimentally. Aim of their study to compare the mechanical properties of GFRP helical spring with steel one in automotive application. They manufactured GFRP springs by filament winding and hand lay-up methods. In the study, composite spring is cured in atmospheric temperature for a day. They determined numerical results on ANSYS. Failure load and deflection of GFRP and steel springs have determined by universal testing machine. The results obtained show that the failure load of composite spring is higher than steel one. According to results, GFRP helical spring is 25% stronger and 200% expensive than steel helical spring. The maximum deflection found from the experimental and numerical results for the both springs matches approximately equal. Results show that the weight of the GFRP springs is less than the conventional steel spring [19].

For the purpose of saving energy and improving the performance of machines, composite materials with light weight and high quality have been widely used for today’s technologies. Therefore, machine elements made by FRP composites, such as helical spring, are attracted the interest of many researchers. All of the researches have provided valuable results on the application of FRP composite helical springs, which is the purpose of this investigation. In this study the various design and manufacturing methodologies of FRP composite helical spring is reviewed and following conclusions are made:

FRP composite helical springs are lighter than conventional steel springs. They can be easily replaced in light weight vehicles with slightly different size. In regular vehicles, both springs, which are made by composite and conventional spring material (steel), can be used to overcome low stiffness of composite materials and weight of steel spring can be optimized.

In the design of helical spring must take into account parameters such as harshness, noise and vibration [18,20,21]. Especially, these parameters are very important issues to design of springs in automotive industry. Related researches show that FRP composite springs are provide ideal characteristics for this aim [1,12,14].

In most cases, FRP composite springs show better mechanical behavior than conventional steel ones. However, composite spring needs a special design process, especially dimensional optimization plays crucial role on the mechanical behavior. Mechanical properties of it can be established by micromechanics approach (analytically). For the analysis purpose ANSYS software is recommended as it gives quite good result.

Investigation shows that carbon fiber reinforced epoxy (thermoset resin) composite, which is known as CFRP, achieve the best mechanical behavior for FRP helical spring design. Also, composite helical spring fabrication is very important to final mechanical properties of its. According to all researches, the best manufacturing process, which is effect positively, can be proposed as combination of filament winding technique (FWT) and resin transfer moulding (RTM).

\It seems that the CNT addition is improve the deformation characteristics of CNT additive CFRP composite helical spring. When CNT volume fraction increases, deformation values become low and spring stiffness value becomes increase. Hence, some weak behaviors of FRP composite helical spring against to conventional steel springs can be overcome by CNT addition into the matrix.

Manufacturing of FRP composite helical springs are quite different and difficult in comparison with conventional steel one. Resin impregnation to fiber and curing process are make complicated the fabrication of its. Shape and geometry of helical or coil springs are problematical for manufacturing systems. Time to produce a FRP composite spring has been quite long in comparison with steel one. Researches are, discussed above, show that there is no many option to produce a FRP composite spring. Mostly researchers have been used FWT to manufactured a FRP composite spring. There are being some researches to improve FWT systems on the fabrication of FRP composite helical spring by many researchers and industrial companies. It seems cost friendly, easy to setup, fast and reliable than all other techniques. On the other hand, RTM has been used by Choi, B. L., & Choi, B. H. to produce a prototype of FRP composite helical spring. It could be provided very high quality and clean product because of the molding system under the vacuum conditions. It is quite convenient fabrication method for single production nevertheless production of it takes long time and high costly as well.

The manufacturing of the FRP composite coil springs is also difficult and time consuming compare to steel spring. Also, CNT addition into the matrix makes more complicated to manufacturing of these helical springs. This could be seen as one of the major disadvantages of the FRP composite springs.

The cost of the overall system is higher than conventional system but because of the other advantages, it can be considerable. For special purpose applications, this system is very much efficient. On the other hand, cost of nanoparticle is quite high in today’s conditions to fabrication of composite elements.

In the open literature, there is limited work on FRP composite helical springs. It is quite new and need more research on real applications. According to researches as we discussed in this paper, mechanical characteristics of FRP composite springs have been determined by different investigations such as analytically, numerically and experimentally. Results show that helical springs made by FRP composite have substantial advantages over the conventional helical metals springs. However, fracture phenomenon of them is play crucial role to use them safely in real application. To use them in real application, breaking of helical spring must be focus point of investigations. On the other hand, all researches investigate the FRP composite springs manufacturing as a single part fabrication. The application of the FRP composite material for helical springs can be justified by producing in mass which will reduce the cost of the composite parts.

I am very grateful to my supervisor Dr. Kolos Molnár (BME, Hungary) and Prof. Dr. Hamit Akbulut (Atatürk University, Turkey) whose provide great support, valuable advices, suggestions and tremendous help to me.

|

Figure 1: FRP Composite coil spring manufacturing by RTM [12] |

|

| Figure 2: Ratio of spring stiffness and density of helical springs made of CNT additive CFRP composites and steel versus wire diameters [1] |

Fiber Content (%) |

Steel spring weight (N) |

Glass/Epoxy composite spring weight (N) |

Carbon/Epoxy composite spring weight (N) |

Kevlar/Epoxy composite spring weight (N) |

0.6 |

30.1 |

7.75 |

4.95 |

5.26 |

0.7 |

30.1 |

8.26 |

5 |

5.36 |

0.8 |

30.1 |

8.77 |

5.05 |

5.46 |

Table 1: Comparison of steel and three different epoxy composite helical springs due to fiber content [13] |

||||

Properties |

Glass Fiber |

Carbon Fiber |

Glass/Carbon Fiber |

Spring Constant (N/mm) |

4.83 |

6.36 |

5.75 |

Maximum Compression (mm) |

83 |

80 |

77 |

Failure Load (N) |

1000 |

1500 |

1200 |

Shear Stress (N/mm2) |

83.00 |

79.67 |

95.49 |

Table 2: The mechanical properties of three types of composite helical springs [14] |

|||

Name of the structure |

AU |

UR |

BU |

BUR |

Materials in the structure |

All unidirection |

Unidirection + Rubber core |

Outer braid + Unidirection |

Outer braid + Unidirection + Rubber core |

Cross-section |

|

|

|

|

Dimensions |

76.53 x 41.5 cm2 |

76.53 x 37.5 cm2 3 mm rubber core |

76.53 x 37.5 cm2 3K carbon fiber outer braid (one layer) |

76.53 x 37.5 cm2 3K carbon fiber outer braid (one layer) |

Table 3: The four kinds of preformed composite bars with different structures [15] |

||||